Products

PRODUCTS CENTER

Related Products

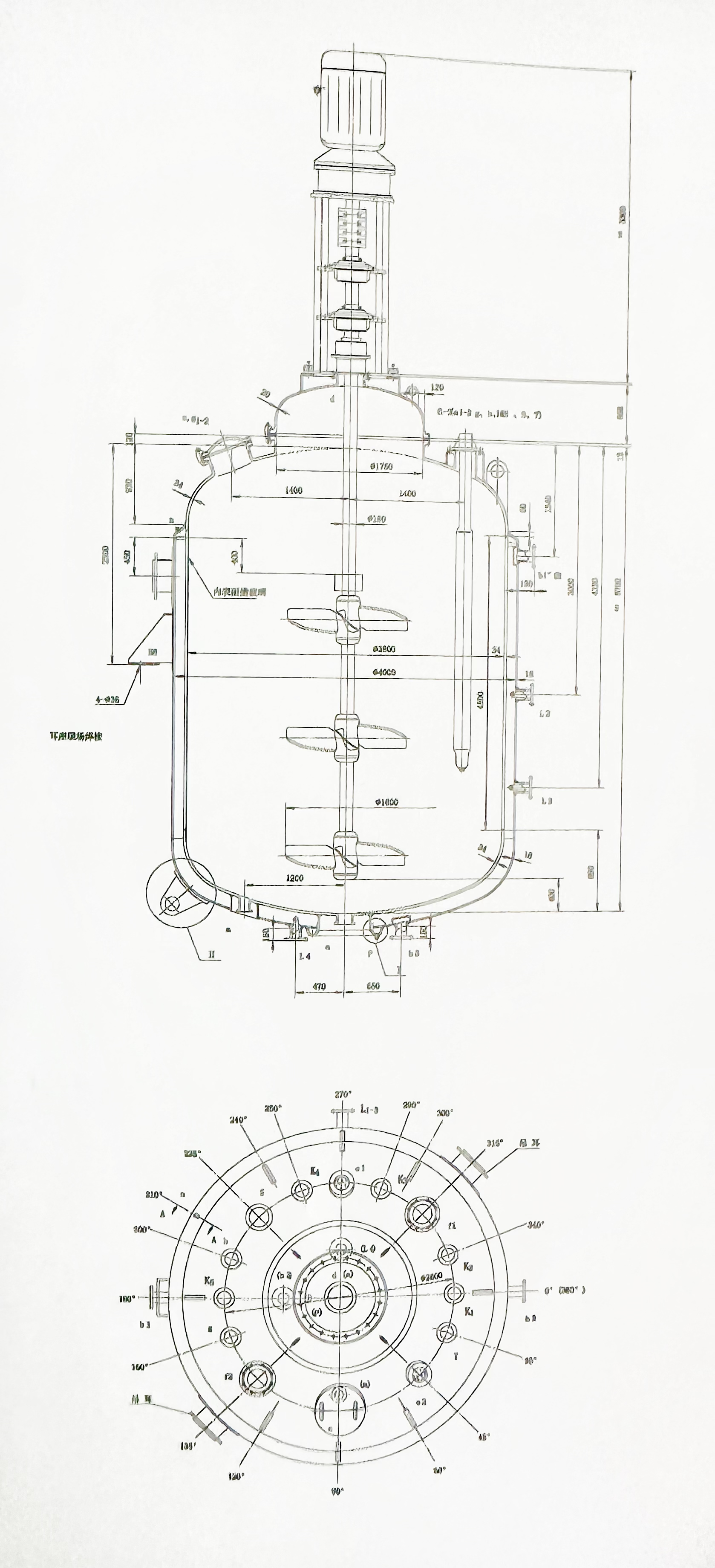

Papua New Guinea F60000L glass-lined reactor

Product Description

| Parameters Table |

Vessel |

Jacket | |||

| Full capacity area m3 |

68.72 |

||||

| Heat exchange area m2 |

/ |

68.2 |

|||

| Design pressure Mpa |

0.4 |

0.6 |

|||

| Design temperature °C |

200 |

200 |

|||

| Steel plate material |

Q345R |

245R |

|||

| Reference weight Kg |

/ |

||||

| High voltage test (kv) |

20 |

||||

| Reducer-helical gear |

RF180 |

/ |

|||

| Motor-asynchronous explosion-proof type KW |

YB45 |

||||

| Frame |

DJ180 |

||||

| Agitator | Anchor, Gate stirrer:63~85r/m Paddle, Impeller:85~130r/m | ||||

| Use medium | Resistance to corrosion of inorganic acids, organic acids, organic soivents and weak alkalis at various concentrations (except hydrofluoric acid,medium containing fluoride ions, con- centration > 30%,temperature>180% concentrated phosphoric acid and strong alkali) |

||||

|

Note: When the working temperature is less than 0°C or the design pressure is greater than 0.4, please specify when ordering |

|||||

|

IV nozzle table |

|||||

|

Symbol |

Nominal size |

Connecting flange standard |

Purpose |

||

|

M/sl |

DN450/125 |

/ |

Manhole (with sight glass) | ||

|

a |

DN200-B |

PNO1.0HG/T2105-2017 |

Spare port | ||

|

b |

DN200-B |

PNO1.0HG/T2105-2017 | Spare port | ||

|

c |

DN200-B |

PNO1.0HG/T2105-2017 | Spare port | ||

|

d |

DN200-B |

PNO1.0HG/T2105-2017 | Spare port | ||

|

e |

DN250-A |

PNO1.0HG/T2105-2017 | Stirrer port | ||

|

f |

DN150-A |

PNO1.0HG/T2105-2017 | Discharge port | ||

|

h |

DN200-B |

PNO1.0HG/T2105-2017 | Spare port | ||

|

s2 |

DN150-A |

PNO.1.0HG/T2144-2018 | Mirror port | ||

|

T1~2 |

DN250-B |

PN1.0HG/T2105-2017 |

Thermometer port | ||

|

L1~4 |

DN125 |

PL100 (B) -10RF |

Steam inlet (outlet) | ||

|

g |

G3/4" |

/ |

Exhaust vent | ||

|

k |

G1/2" |

/ |

Discharge outlet | ||

The F60000L glass lined reactor is a high-performance industrial reactor designed for large-scale chemical processing, offering superior corrosion resistance, durability, and efficiency. With a 60000L capacity, this glass lined reactor is ideal for industries such as pharmaceuticals, chemicals, and petrochemicals, where highly reactive or corrosive substances require safe and reliable processing.

Constructed with a high-quality glass lining, the F60000L glass lined reactor ensures exceptional chemical stability, preventing contamination and ensuring the purity of the processed materials. The smooth, non-porous surface minimizes product adhesion and facilitates easy cleaning, reducing downtime between batches. Its robust design withstands high temperatures and pressures, making it suitable for a wide range of chemical reactions, including polymerization, hydrolysis, and synthesis.

The F60000L glass lined reactor is equipped with advanced mixing technology, ensuring uniform heat distribution and efficient reaction control. The precisely engineered agitation system enhances mass transfer and reaction consistency, optimizing production efficiency. Additionally, the reactor’s jacketed structure allows for precise temperature regulation, ensuring stable processing conditions for even the most sensitive reactions.

Designed for operational safety, the F60000L glass lined reactor includes high-strength construction, leak-proof sealing, and pressure-resistant features to prevent failures during operation. Its corrosion-resistant glass lining extends the equipment's service life, reducing maintenance costs and enhancing long-term performance. Furthermore, it integrates seamlessly with automated control systems, providing real-time monitoring and precise adjustments for enhanced process control.

RELATED PRODUCTS