Blog

Durable Glass Lined Reactor

Release time:

Feb 05,2025

Information Summary:

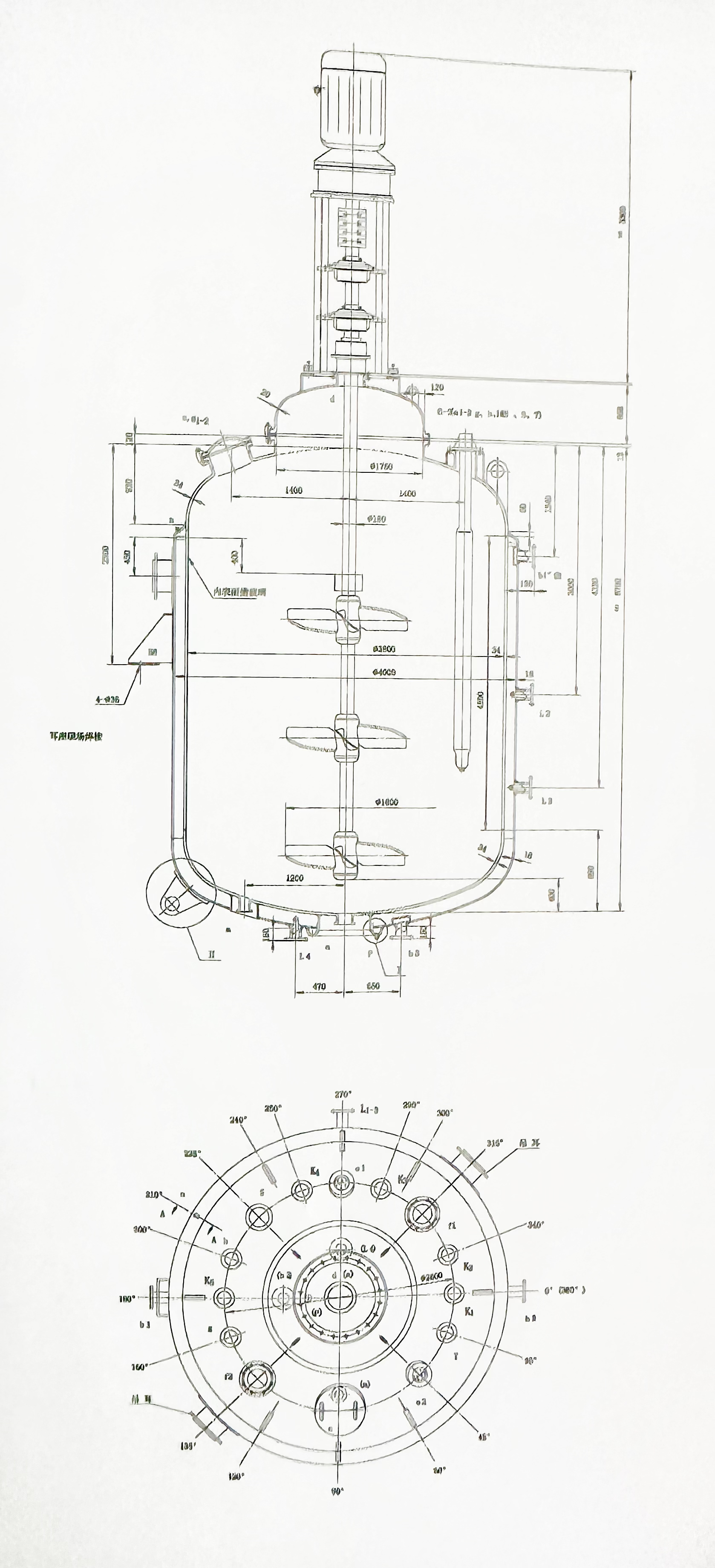

| Parameters Table | Vessel | Jacket | |||

| Full capacity area m3 | 68.72 | ||||

| Heat exchange area m2 | / | 68.2 | |||

| Design pressure Mpa | 0.4 | 0.6 | |||

| Design temperature °C | 200 | 200 | |||

| Steel plate material | Q345R | 245R | |||

| Reference weight Kg | / | ||||

| High voltage test (kv) | 20 | ||||

| Reducer-helical gear | RF180 | / | |||

| Motor-asynchronous explosion-proof type KW | YB45 | ||||

| Frame | DJ180 | ||||

| Agitator | Anchor, Gate stirrer:63~85r/m Paddle, Impeller:85~130r/m | ||||

| Use medium | Resistance to corrosion of inorganic acids, organic acids, organic soivents and weak alkalis at various concentrations (except hydrofluoric acid,medium containing fluoride ions, con- centration > 30%,temperature>180% concentrated phosphoric acid and strong alkali) | ||||

Note: When the working temperature is less than 0°C or the design pressure is greater than 0.4, please specify when ordering | |||||

IV nozzle table | |||||

Symbol | Nominal size | Connecting flange standard | Purpose | ||

M/sl | DN450/125 | / | Manhole (with sight glass) | ||

a | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

b | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

c | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

d | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

e | DN250-A | PNO1.0HG/T2105-2017 | Stirrer port | ||

f | DN150-A | PNO1.0HG/T2105-2017 | Discharge port | ||

h | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

s2 | DN150-A | PNO.1.0HG/T2144-2018 | Mirror port | ||

T1~2 | DN250-B | PN1.0HG/T2105-2017 | Thermometer port | ||

L1~4 | DN125 | PL100 (B) -10RF | Steam inlet (outlet) | ||

g | G3/4" | / | Exhaust vent | ||

k | G1/2" | / | Discharge outlet | ||

The Glass Lined Reactor is a versatile and highly durable solution designed for chemical processing industries, including pharmaceuticals, dyes, and petrochemicals. This advanced reactor combines the strength of high-grade carbon steel with a protective glass lining, offering superior resistance to corrosion, chemical reactions, and thermal stress. The smooth and inert surface of the glass lining ensures minimal contamination, making it ideal for handling aggressive chemicals and maintaining product purity.

With exceptional thermal stability, the Glass Lined Reactor supports efficient heat transfer for precise temperature control, even in high-pressure environments. Its robust design allows for safe operation in demanding production settings, enhancing both safety and productivity. The reactor's superior corrosion resistance reduces maintenance requirements, ensuring long-term operational reliability and cost-efficiency.

Whether you need batch processing or continuous production, the Glass Lined Reactor offers unparalleled performance and adaptability. Its customizable features and adherence to international safety standards make it a reliable choice for industries that demand high-quality chemical processing equipment.

Related News

2025-02-05