Products

Products

Tel

Related Products

ZK (conical open) glass lined reactor

Product classification

Key words:

ZK (conical open) glass lined reactor

ZK conical open glass lined reactor

- Details

-

- Commodity name: ZK (conical open) glass lined reactor

Conical open glass-lined reactor equipment features: design and manufacture according to HG2432 and GB150 standards. This structure combines the advantages of open glass-lined reactors.

Product Description:

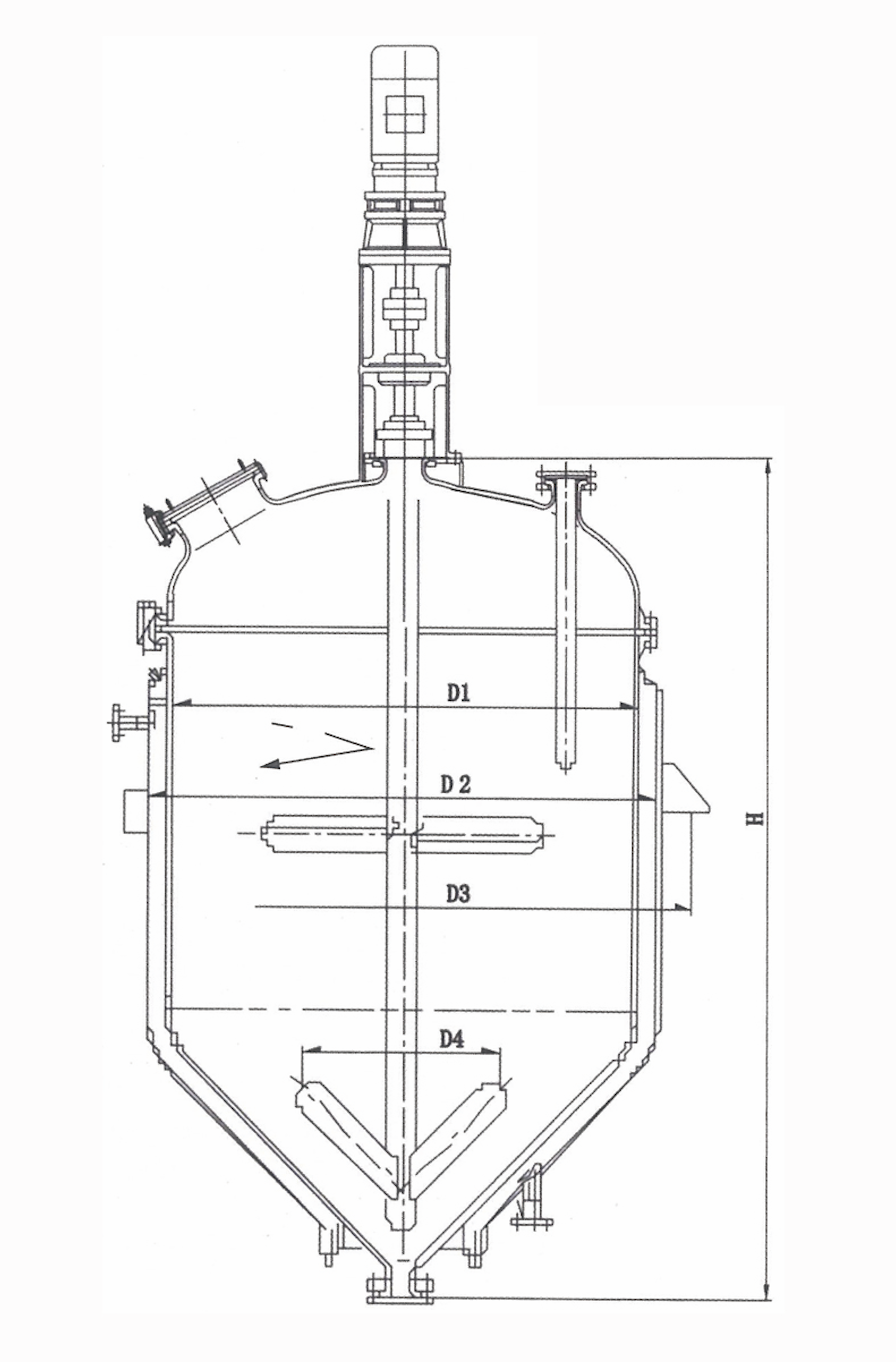

Conical open glass-lined reactor equipment features: design and manufacture according to HG2432 and GB150 standards. This structure combines the advantages of open glass-lined reactors. The lower cone structure makes the concentration and crystallization of the glass-lined reactor more reasonable. It can meet the needs of different users' crafts.

The design standard of the nozzle of the conical closed glass-lined reactor equipment is in accordance with the K open-type glass-lined reactor.

ZK (conical closed) glass lined reactor Vessel Jacket Packing seal Mechanical seal Design pressure (Mpa) < 0.1 ≤0.4

0.6

Design temperature (°C) 200

Working temperature (°C) 0-160

Porcelain layer thickness (mm) 0.8-2.0

Withstand voltage test (kv) 20

Rapid change in heat resistance (°C) Cold shock 110 Thermal shock 120 Standard mixing type Paddle Note: When the working pressure in the equipment is> 0.4Mpa, the working temperature is lower than 0°C, the working pressure of the jacket is> 0.6Mpa, and the non-standard mixing type must be specified when ordering. series ZK conical closed glass lined reactor model ZK2000

ZK3000

ZK4000

ZK5000

ZK6300

Nominal volume (L) 2000

3000

4000

5000

6300

Actual volume (L) 2160

3237

4255

5435

7570

Heat exchange area (m2) 7.02

8.61

11.7

13.3

16.0

D1mm

1300

1600

1600

1750

1750

D2mm

1450

1750

1750

1900

1900

D3mm

1639

1960

1960

2152

2152

D4mm

680

720

720

720

720

H(mm)

2900

3360

3630

3850

4020

Checking Hole( mm)

300x400

300x400

300x400

300x400

300x400

Key words:- ZK (conical open) glass lined reactor

Previous

YongZheng 80000L Glass lined storage tank

YongZheng 50000L stainless steel triple effect product: reaction,separation,crystallization

RELATED PRODUCTS