Blog

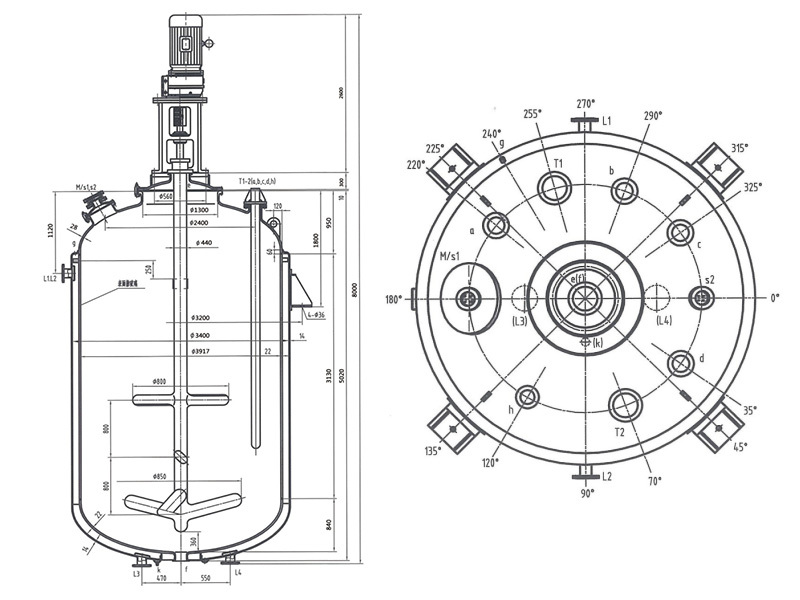

Quality F30000l Glass Lined Reactor

Release time:

May 06,2025

Information Summary:

| Parameters Table | Vessel | Jacket | |||

| Full capacity area m3 | 34.5 | ||||

| Heat exchange area m2 | / | 44.15 | |||

| Design pressure Mpa | 0.6 | 0.6 | |||

| Design temperature °C | 200 | 200 | |||

| Steel plate material | 345R | 245R | |||

| Reference weight Kg | 19900(Without transmission equipment) | ||||

| High voltage test (kv) | 20 | ||||

| Reducer-helical gear | RF137 | RF147 | |||

| Motor-asynchronous explosion-proof type KW | YB37 | ||||

| Frame | DJ130 | ||||

| Agitator | Paddle, Impeller: 85~130r/m | ||||

| Use medium | Resistant to corrosion of various concentrations of inorganic acids, organic acids, organic solvents and weak bases (except for hydrofluoric acid, fluoride ion-containing media, concentration> 30%, temperature> 180% concentrated phosphoric acid and strong alkali) | ||||

Note: When the working temperature is less than 0°C or the design pressure is greater than 0.4, please specify when ordering | |||||

IV nozzle table | |||||

Symbol | Nominal size | Connecting flange standard | Purpose | ||

M/sl | DN450/125 | / | Manhole (with sight glass) | ||

a | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

b | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

c | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

d | DN200-B | PNO1.0HG/T2105-2017 | Spare port | ||

e | DN200-A | PNO1.0HG/T2105-2017 | Stirrer port | ||

f | DN150-A | PNO1.0HG/T2105-2017 | Discharge port | ||

h | DN125-B | PNO1.0HG/T2105-2017 | Spare port | ||

s2 | DN125-A | PNO.1.0HG/T2144-2018 | Mirror port | ||

T1~2 | DN200-B | PN1.0HG/T2105-2017 | Thermometer port | ||

L1~4 | DN100 | PL100 (B) -10RF | Steam inlet (outlet) | ||

g | G3/4" | / | Exhaust vent | ||

k | G1/2" | / | Discharge outlet | ||

The F30000L glass lined reactor is designed for optimal thermal performance and mixing efficiency. It includes robust agitation systems, jacketed heating and cooling features, and precision control interfaces for temperature and pressure regulation. These features allow users to maintain ideal reaction conditions, improving batch consistency and overall yield.

In addition to its performance advantages, the F30000L glass lined reactor is built with operator safety and maintenance in mind. It features smooth internal surfaces for easy cleaning and minimal residue buildup, as well as safety mechanisms that meet global industrial standards. The design also supports integration with automated control systems for seamless operation within modern production environments.

Whether used for synthesis, crystallization, polymerization, or blending, the F30000L glass lined reactor offers a reliable and efficient solution for complex processing requirements. Its long service life, chemical inertness, and high-volume handling capabilities make it an invaluable asset in any large-scale manufacturing setup.

Related News

Quality F30000l Glass Lined Reactor

2025-05-06